What is chipboard used for?

What is chipboard used for?

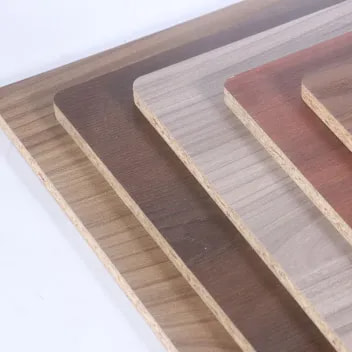

Chipboard is commonly used for various applications in construction, furniture manufacturing, and packaging industries. It is a type of engineered wood product made from wood chips, sawdust, and adhesive binders compressed and formed into sheets.

The primary use of chipboard is in the production of furniture and cabinetry. It is often utilized as a core material for inexpensive furniture pieces such as shelves, cabinets, and bookcases. Chipboard provides a stable and cost-effective substrate for laminates, veneers, and other decorative finishes commonly used in furniture manufacturing. Its affordability and versatility make it a popular choice for mass-produced furniture items.

In the construction industry, chipboard finds applications in interior finishing work such as wall paneling, flooring underlayment, and acoustic insulation. It is favored for its lightweight nature and ease of installation, making it suitable for both residential and commercial projects. Additionally, chipboard is used as a temporary formwork in concrete construction, providing support for freshly poured concrete until it cures.

Moreover, chipboard is widely employed in the packaging industry for the manufacture of cardboard boxes, cartons, and other packaging materials. Its ability to provide strength and rigidity to packaging while remaining lightweight makes it ideal for protecting goods during storage and transportation. Chipboard packaging is commonly used in industries such as food and beverage, pharmaceuticals, electronics, and consumer goods.

The versatility and affordability of chipboard have contributed to its widespread adoption across various industries. Its composition and manufacturing process allow for customization of thickness, density, and surface finish to meet specific application requirements. Additionally, chipboard is considered an environmentally friendly alternative to solid wood, as it utilizes recycled wood fibers and reduces waste in the manufacturing process.

However, it is important to note that chipboard has limitations in terms of strength, durability, and moisture resistance compared to other wood-based products such as plywood or medium-density fiberboard (MDF). Therefore, its suitability for different applications should be carefully evaluated based on factors such as load-bearing requirements, environmental conditions, and desired lifespan.

In summary, chipboard is a versatile and cost-effective engineered wood product used in furniture manufacturing, construction, and packaging industries. Its widespread availability, ease of customization, and eco-friendly properties make it a valuable material for various applications. However, its limitations should be considered when selecting it for specific projects to ensure optimal performance and longevity.

- Previous: None

- Next: None